Mining industry highly depends on accuracy. Cost and revenue calculations, sales forecasting, operational planning and other recurring tasks require constant tracking of the activities. What is the current state of the mine? What volume of gravel was removed? How much can be deposited in the future?

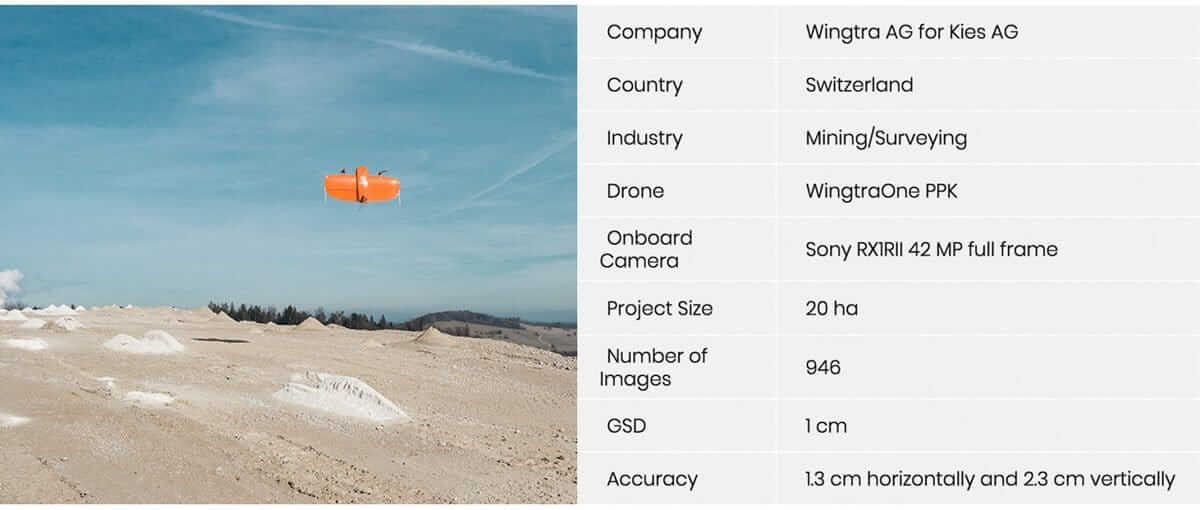

At Kies AG, the answers to these questions have long depended on helicopter photogrammetry, but Wingtra decided to challenge the status quo. After performing test flights with a WingtraOne mapping drone over their two mines and a data post processing workshop with Pix4Dmapper, Wingtra handed Andy Gerber, the manager at Kies AG, quite a different set of results than he was used to.

VTOL WingtraOne drone surveys improve the operations in mining: save time & significantly increase the accuracy

Kies AG Glattfelden is an independent company performing gravel extraction, treatment and landfill of excavated material. The company has also been supplying gravel in various forms and quantities from mines in the north of the canton of Zurich for more than 35 years. Besides gravel and its products, such as block stones or decorative gravel, Kies AG produces concrete and is now an established player in the market.

To keep track of their two mines, Haberland and Ziegli, Kies AG uses machine guidance and helicopter photogrammetry. Andy Gerber, the Manager at Kies AG, explains: “During the year, we use excavators with machine guidance based on GPS at Haberland and Zelgli mines. We use them to track the volume of excavated materials and to monitor where the work is done. In the past it was done with manual land surveying techniques.”

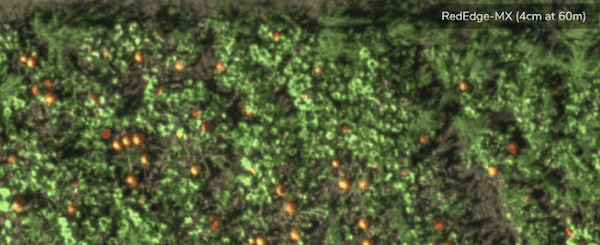

Apparently, machine guidance is not enough as later explained by Andy Gerber. To ensure the accuracy of the collected data, Kies AG performs yearly helicopter surveys, which are used to calculate the volume of rock that was extracted, monitor movements and deformations, forecast the development of the mine, and plan for the future.

Usually the data collection with a helicopter lasts around two days, but it takes much longer to receive the final output – sometimes, even as long as a couple of months. In addition, Andy Gerber receives analog data in print and already executed volume calculations that he cannot reuse digitally. Regarding data accuracy, helicopter surveys usually reach the accuracy of 5 cm.

The project

Wingtra team offered Kies AG an easy way of comparing two different ways of aerial data collection. The team would organize a series of test flights and a data post-processing workshop with Pix4Dmapper. Kies AG would be able to uate the process and get involved in it.

During the Kies AG project, Wingtra mapping team took no longer than 1 day from the start of the mission to the final results. The VTOL drone WingtraOne was used to collect aerial data of a 20 ha mine. Later this data was post-processed with both Pix4Dmapper desktop and cloud, and results were more than satisfying. The joint survey produced extremely accurate results with the absolute accuracy reaching down to 1 cm, which compared to the helicopter’s 5 cm, is a significant step forward.

Accurate survey data is crucial for the mining business processes: production forecasting, operational planning, financial and legal matters

When asked what Kies AG usually uses the survey results for, Andy commented: “The surveys help to track our business operations, plan finance and abide by legal matters. First we compare results with the data collected with machine guidance (excavators) and the current state of the quarry. It helps to judge what can be done with the two quarries, how much gravel can be removed, how much can be deposited in the future.”

The process is tightly linked to business financials in mining that help with forecasting sales volumes and revenues. Depending on the volumes predicted for the upcoming year, Kies AG office calculates how much gravel can be dug and distributed, which results in clearer analysis of expenditure, income and finally revenue. It not only makes internal operations much smoother, but also gives their external stakeholders a clearer idea of what to expect from Kies AG.

Finally, the data also allows the surveyors to know the exact volume of the materials which is removed from the mines. That is crucial for legal matters as defined borders shouldn’t be exceeded. Otherwise Kies AG office would have to re-cultivate the mine. In this respect, using the drone and photogrammetric information becomes a risk management tool that reduces the uncertainty the company is facing on a day to day operation.

When asked whether Andy Gerber would consider switching from helicopter conducted surveys to drone photogrammetry, Andy nodded in agreement. “We are used to the helicopter way, but now I can clearly see the advantages of drone photogrammetry. The ease of use of the drone, much faster process and significantly higher data accuracy would help us be more efficient in mine operations”.